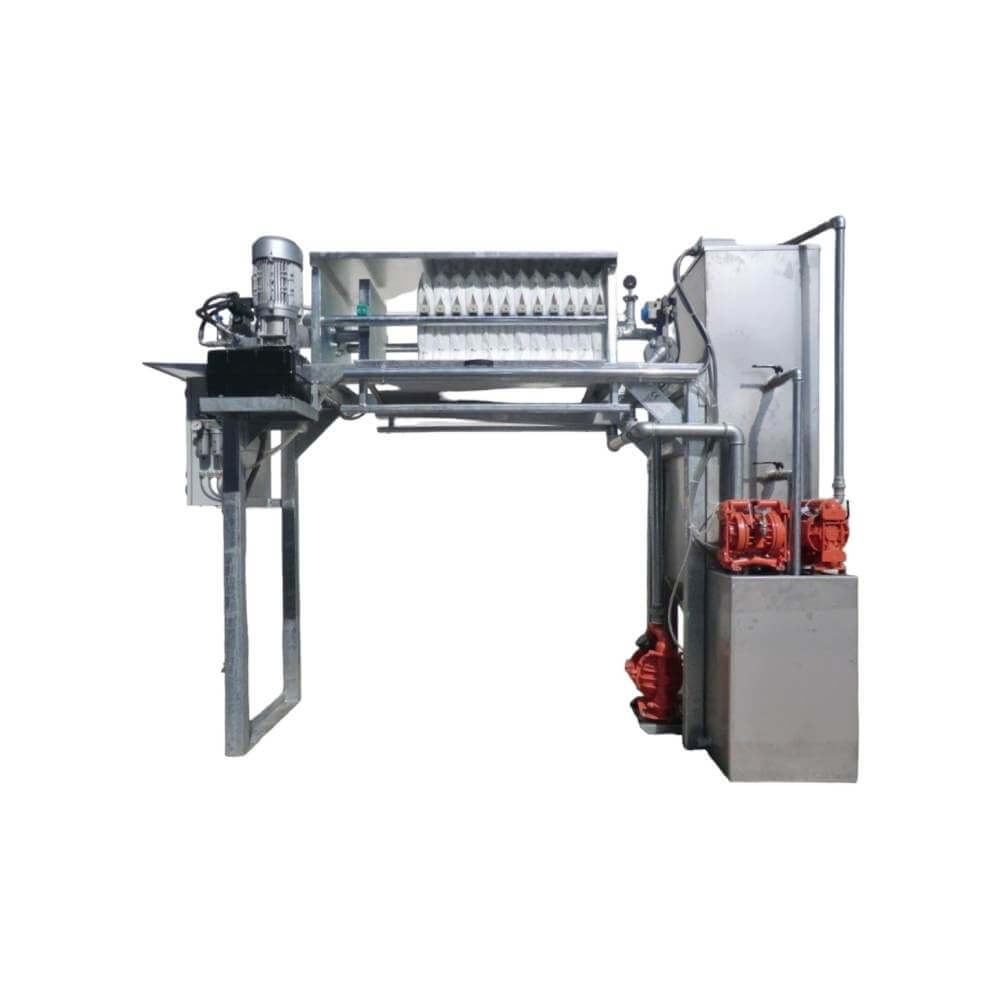

Filter press for sludge dehydration.

The sludge dehydration through FILTER PRESS is the most used process to separate solids from liquids.

HOW WORKS THIS PROCESS OF SLUDGE DEHYDRATION THROUGH FILTER PRESS?

This process takes place through the pressure created inside the filter chambers by special pumps. The AS filter is applied where there is the possibility of having fast and optimal filtration and ensures safe and quick panel release.

All models are built inelectro-welded steel and treated with special painting or hot galvanizing according to the customer’s needs. Parts in contact with the liquid are made of aluminum alloy or stainless steel. Plates are available in fixed or variable volume for more complex problems. The machines are supplied already tested and compliant with CE regulations.

Fully automatic for easy installation and reliability on any type of mud.

The serie AS offers a wide range of models from 300×300 to 1500×1500, to meet different flow rate needs and can be equipped with:

- perimeter walkways,

- Support structure made of electro-welded steelwork,

- external protective cover,

- Filter cloth washing device,

- Various automatisms.

👇FILL IN THE FORM TO REQUIRE A QUOTE

AND CHOOSE THE BEST PRODUCT FOR YOU!👇

| Brand |

Filter Project |

|---|

FILL OUT THE FORM TO REQUEST A QUOTE

No account yet?

Create an AccountTo stay updated on all our products and services

SUBSCRIBE TO OUR NEWSLETTER!

GET A WELCOME DISCOUNT!